Unlocking the Power of Smart Valve Automation In India

India's process industries, encompassing sectors like oil and gas,

chemicals, pharmaceuticals, and power, are at the cusp of a transformative

shift, driven by the rapid advancements in valve automation technologies. As

the country gears up for landmark events like Automation Expo 2025 and

Automation Expo South 2025, it is crucial to explore the latest trends shaping

the future of valve automation and its profound impact on process efficiency, safety, and

sustainability.

The

Rise of Smart Valve Integration

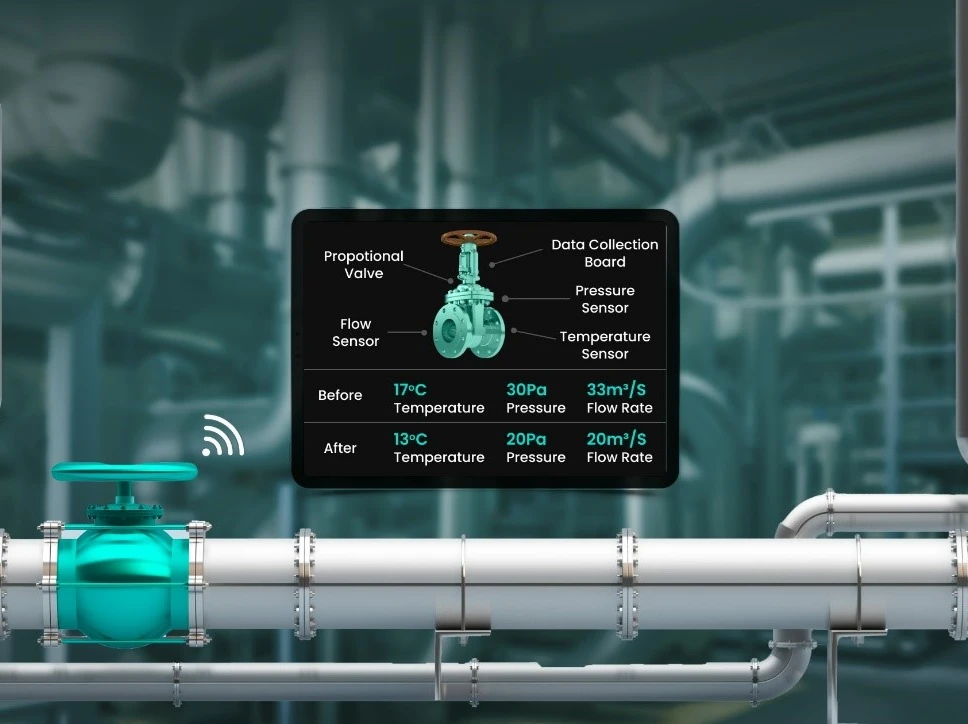

The era of Industry 4.0 has ushered in a new generation of

intelligent valve systems that seamlessly integrate with plant-wide control and

monitoring networks. These smart valves are equipped with advanced sensors,

actuators, and communication protocols, enabling real-time data collection,

remote diagnostics, and predictive maintenance capabilities. This integration

not only enhances process control but also reduces downtime and maintenance

costs.

Leading valve manufacturers are showcasing their state-of-the-art

smart valve solutions at Automation Expo 2025, catering to the growing demand

for intelligent process control in India's industrial landscape. These smart

valves leverage Industrial Internet of Things (IIoT) technologies to provide

plant operators with unprecedented visibility and control over their critical

valve infrastructure.

Wireless

Valve Automation

Redefining Flexibility and Accessibility Driven by the increasing

adoption of IIoT, wireless valve automation is gaining traction in India's

process industries. Wireless valve positioners and controllers eliminate the

need for costly wiring and conduit infrastructure, simplifying installation and

enabling greater flexibility in plant layouts. This technology also facilitates

remote monitoring and control, improving operational efficiency and reducing

manual intervention.

Leading valve automation companies will prominently showcasing their wireless valve solutions at Automation Expo South 2025, highlighting the transformative potential of this technology in enhancing accessibility and flexibility for process plants across India.

Cybersecurity

Safeguarding the Heart of Process Control As process industries

become increasingly digitalized, the importance of robust cybersecurity

measures in valve automation systems cannot be overstated. Manufacturers are

now integrating advanced encryption, access controls, and secure communication

protocols to safeguard critical valve infrastructure from cyber threats. This

heightened focus on cybersecurity ensures the integrity and reliability of

valve automation systems, a key consideration for process industries.

Industry players are addressing this imperative by showcasing

their cutting-edge cybersecurity solutions for valve automation at Automation

Expo 2025. These technologies not only protect against malicious attacks but

also provide real-time visibility and anomaly detection, enabling plant

operators to maintain the highest levels of process control security.

Predictive

Maintenance and Analytics

Optimizing Valve Performance The integration of advanced analytics

and machine learning algorithms with valve automation systems is

revolutionizing maintenance strategies. By continuously monitoring valve

performance, these predictive maintenance solutions can detect early signs of

wear and tear, enabling proactive interventions and minimizing unplanned

downtime. This data-driven approach not only optimizes maintenance schedules

but also extends the lifespan of critical valve components.

Prominent valve manufacturers are leading the charge in this

domain, showcasing their predictive maintenance platforms at both Automation

Expo 2025 and Automation Expo South 2025. These solutions leverage real-time

data from smart valves to provide plant operators with actionable insights,

empowering them to make informed decisions and maintain optimal process control.

Sustainability

and Energy Efficiency

Aligning with India's Green Agenda as India's process industries

strive to reduce their environmental footprint, valve automation technologies

are playing a pivotal role. Intelligent valve systems can optimize energy

consumption, minimize fugitive emissions, and enable more sustainable process

control, contributing to the industry's overall sustainability goals. This alignment

with the nation's sustainability agenda is expected to drive further

advancements in valve automation at events like Automation Expo 2025.

Leading companies will be showcasing their eco-friendly valve

solutions at the expo, highlighting the critical role of valve automation in

supporting India's ambitious sustainability targets. These technologies not

only enhance process efficiency but also contribute to the country's broader

decarbonization efforts, positioning the process industries as responsible and

forward-thinking stakeholders.

These transformative trends in valve automation are poised to reshape the process control landscape in India, driving increased efficiency, safety, and sustainability across various industries. As the country prepares for the upcoming Automation Expo 2025, Mumbai and Automation Expo South 2025, Chennai, the spotlight will undoubtedly shine on the latest valve automation innovations that are redefining the future of process industries in India.